Repuestos de coche baratos al por mayor

autopartes, autopartes al por mayor, autopartes de posventa, autopartes, repuestos para autos. Personalización rápida de piezas de repuesto para automóviles, solo envíenos muestras o dibujos originales.

autopartes, autopartes al por mayor, autopartes de posventa, autopartes, repuestos para autos. Personalización rápida de piezas de repuesto para automóviles, solo envíenos muestras o dibujos originales.

La fábrica de doblado CNC ofrece servicio de doblado de tubos de metal CNC. Fábrica de plegado CNC fabricada en China Nuestra fábrica ofrece servicio de doblado de tubos CNC. Servicio de plegado CNC disponible Curvado CNC OEM Doblado de metal CNC de la mejor calidad

Brindamos servicios OEM ODM para estampado de metal, estampado de acero inoxidable. Nuestra fábrica tiene más de 25 años de experiencia en estampación de chapa metálica de precisión. Estampado de metal de gran volumen con precio de fábrica. Estampado de metal de alta precisión fabricado en China.

Custom stainless steel shelf metal wall brackets

Metal shelf brackets are hardware components used to support and stabilize shelves, typically mounted to walls. They come in a variety of shapes, sizes, and finishes, depending on your shelving needs (e.g., for heavy-duty storage, decorative shelving, or floating shelves).

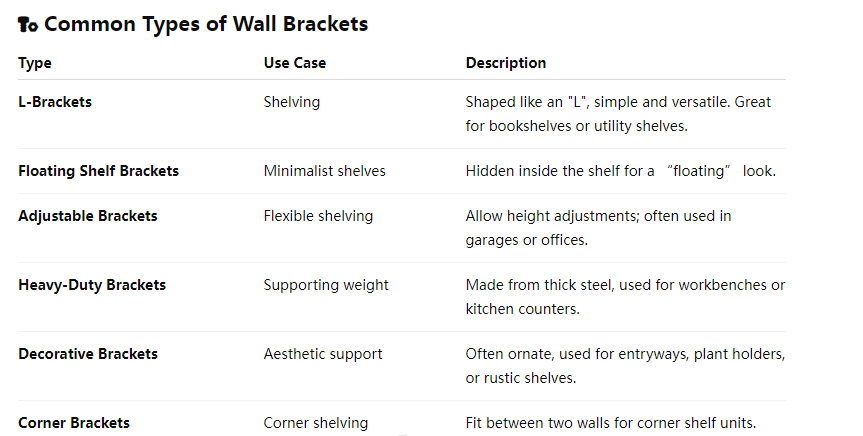

Common Types of Metal Shelf Brackets:

1. L-Shaped Brackets – Classic right-angle design; easy to install and sturdy.

2. Heavy-Duty Brackets – Made from thicker metal for garages, workshops, or warehouses.

3. Floating Shelf Brackets – Hidden inside the shelf for a minimalist look.

4. Decorative Brackets – Often ornate or styled, combining function and design.

5. Adjustable Brackets – Used with wall-mounted tracks, ideal for flexibility.

Materials and Finishes:

Steel (often powder-coated or painted)

Stainless Steel (resistant to rust, good for kitchens/bathrooms)

Aluminum (lightweight, corrosion-resistant)

Stainless steel shelf brackets are durable, corrosion-resistant supports used to mount and hold shelves. They’re commonly used in kitchens, bathrooms, garages, and commercial spaces where strength and resistance to moisture or chemicals are important. Here's a quick guide to choosing the right stainless steel shelf brackets:

Types of Stainless Steel Shelf Brackets

1. L-Brackets (Angle Brackets)

Basic right-angle design

Great for lightweight to medium loads

Simple and clean aesthetic

2. Floating Shelf Brackets

Hidden inside the shelf for a minimalist look

Often used with thick, solid wood shelves

3. Heavy-Duty Industrial Brackets

Reinforced or gusseted for high load capacity

Ideal for garages, workshops, or commercial kitchens

4. Adjustable Brackets

Allow repositioning of the shelf height

Used with track or rail systems

Key Considerations

Material Grade:

304 stainless steel: Most common, good corrosion resistance

316 stainless steel: Higher corrosion resistance (marine-grade), ideal for humid or coastal environments

Weight Capacity:

Check the manufacturer’s load rating—depends on bracket size, wall anchors, and shelf material

Bracket Size:

Depth should match or slightly exceed the depth of the shelf for optimal support

Finish:

Polished, brushed, or matte—choose to match decor

Weight Capacity — Know how much weight the bracket needs to support.

Wall Type — Drywall, brick, or concrete walls may require different anchors or screws.

Bracket Material — Steel (for strength), aluminum (for light loads), or cast iron (for decor).

Shelf Depth — Bracket arms should reach at least ⅔ the depth of the shelf.

Style Preference — Match the bracket finish to your room: black matte, white, chrome, etc.